Many businesses make the mistake of believing the cost of oil is only what they see on the price tag. What they often fail to realize is that there are additional costs such as labor expenses that contribute more to just the tag price. A $5 gallon of gas can sometimes cost a business nearly 40x that when considering the labor involved to making the gas function appropriately.

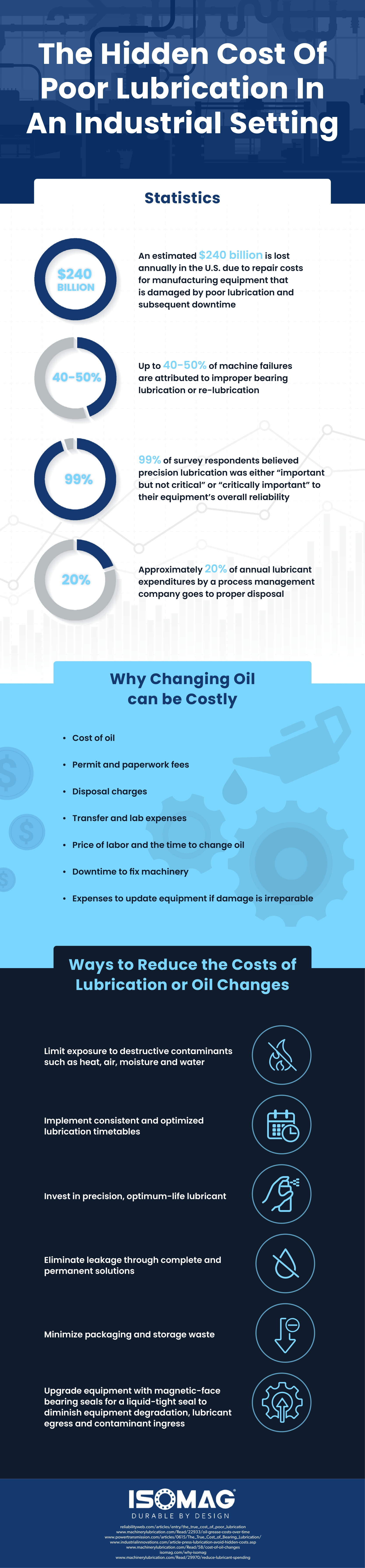

Every business is interested in optimizing their cost effectiveness, especially in regards to machinery. This requires each piece of equipment to be performing at optimal levels. Which requires maintenance such as proper lubrication and completing regular oil changes. Finding a schedule that allows all equipment to be serviced regularly while still partaking in operations is difficult. With this post and accompanying infographic, the process of identifying hidden costs due to mismanaged lubrication in industrial settings will be detailed.

One of the hidden costs that would otherwise be not considered are the unnecessary oil changes organizations conduct. Organizations often schedule an oil change in hopes that it’ll resolve a problem that’s entirely unrelated to an oil change. Organizations waste valuable resources and time by doing this. Worse of, though, they’re emitting additional hazardous waste into to the environment.

Though they may not seem hidden, damage costs are often extremely expensive for organizations to resolve. Often times these damages are related to over or under-filling the sump or reservoir, introducing contaminated or incorrect product and even cross threading a drain plug. The true hidden costs of this damage come in the form maintenance and subsequent downtime. In addition, these costs can also rack up administrative purchasing costs, storage, handling and testing costs for an organization.

Equipment failure is also another hidden cost in that the damages will require maintenance to resolve, but if they’re not resolved, the equipment remains incapable of operating. When considering the most common reason for machine malfunctions, organizations should be weary of bearing issues. Nearly half of all machine failures are a result of improper lubrication or re-lubrication of bearings. Though organizations may be tempted to replace the bearings, shafting or motors of a machine, if nothing is fixed despite the investment, that loss of capital can be detrimental.

For any organization struggling with their lubrication needs or misunderstanding the needs of their machinery, here are some closing tips. Taking a preventive approach could look something like re-engineering fixtures with better seals or filtration equipment. Alternatively, taking current machinery and making improvements such as cutting-edge seals can also help reduce machine downtime. If your organization was hoping to learn more about some of the hidden costs associated with poor lubrication, please take a moment to check out the infographic paired alongside this post. Courtesy of Isomag.